What is anodizing?

Anodizing (or anodising) is an electrochemical process used to increase the thickness of the natural oxide layer on the surface of metal parts. The process is referred to as "anodizing" because the parts to be treated form the anode electrode of an electrical circuit.

Anodic films are most commonly applied to protect aluminum alloys, although other nonferrous metals, such as magnesium, titanium, zinc, niobium and tantalum can also be anodized.

The anodize plating process changes the microscopic texture of the surface and changes the crystal structure of the metal near the surface. Thick coatings are normally porous, so a sealing process is often needed to achieve corrosion resistance. Anodized aluminum surfaces, for example, are harder than aluminum but have low-to-moderate wear resistance that can be improved with increasing thickness or by applying suitable sealing substances.

What are the advantages of metal anodizing?

- Corrosion resistance

- Wear resistance

- Provides better adhesion for paint primers and glues

- Prevents galling of threaded components

- Incredibly hard coated surfaces

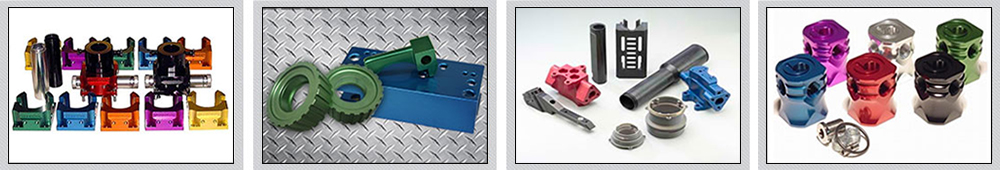

- Retains dyes and lubricants - This ability allows numerous colors to be utilized. This enhances the appearance while protecting the treated metal or alloy.

- Environmentally safer - produces few, if any harmful environmental effects

AFT's Production Capacity

- High volume rack and barrel

- 14 ft tank

- Parts up to 7 ft. or 84 inch in length

- Parts up 2,000 lbs. in weight

- Most anodizing colors available

- Aluminum, titanium, and other metals

Specifications

- RoHS Compliant

- MIL - A - 8625

- Type II and III

- Can meet most private specs

Purchase from AFT or Supply Your Own Parts

When having parts anodized at our metal finishing facility, AFT offers customers the option to either supply their own parts or purchase them directly through AFT. In most circumstances, buying the parts directly from AFT can be significantly less expensive due to lower shipping costs and our competitive pricing.

We offer low minimums, and turn-around times are typically within 7 days. Please contact us with any questions or to request a quote.