What is Zinc Nickel Plating?

The Zinc Nickel plating process provides over 1,000 hours of salt spray protection. Our RoHS compliant Zinc Nickel exceeds the protection of zinc and cadmium plating. Today in the industrial finishing industry there are higher standards and requirements for corrosion resistance, and we help you meet or exceed these standards.

These new standards for corrosion exceed the abilities of traditionally used finishes such as zinc and cadmium. AFT offers an alternative: our Zinc Nickel finishing process. This process outperforms conventional zinc plating. By producing a Zinc Nickel alloy, this outcome outlasts traditional zinc in corrosion resistance and protects for a longer period. Chromating produces a Zinc Nickel alloy chromate film that is rich in nickel, which increases the corrosion resistance of Zinc Nickel.

Zinc Nickel provides better corrosion resistance, making AFT’s Zinc Nickel plating process a perfect alternative to conventional zinc for any steel part intended for exterior use. Zinc Nickel provides the most economical corrosion protection available today.

What are the benefits of Zinc Nickel plating?

- WEEE, ROHS and EVL compliant trivalent passivation (Chrome 6 Free).

- High thermal resistance (up to 200˚C) makes it suitable for high temperature automotive applications.

- Provides Superior Corrosion Resistance – protects the base metal for over 1000 hours to red rust.

- Around four times the hardness and therefore wear resistance of standard Zinc plating.

- Many of these features make Zinc-Nickel and environmentally friendly alternative for Cadmium plating.

Zinc Nickel Specifications

- ASTM B841-99

- AMS 2417

- Can Meet Most Private Specs

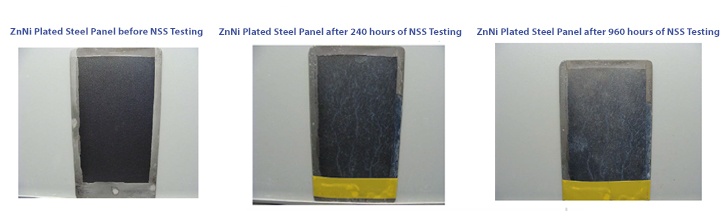

Zinc Nickel Salt Spray Testing

Sample Description: Zinc-Nickel plated steel panel - ZnNi/TriPass ELV 3000 chromate/HydroKlad sealer (ASTM F1941-10 FE ZN Ni 8TF)

Summary:

One (1) sample was tested for Neutral Salt Spray (Fog) Testing (NSS Test) per ASTM B117-16

One (1) sample was exposed to 960 hours of continuous NSS testing

Preventative Maintenance / Calibration on this unit was completed on September 2016 and is next due by September 2017.

Completion Date: February 13, 2017

Method: ASTM B117

| WB = White Blush; WC = White Corrosion; RR = Red Rust | |

| ZnNi Plated Steel Panel | |

| 240 Hours | WB, No WC |

| 960 Hours | No RR |

All procedures were performed in accordance with ASTM B117. The information contained in this test report represents only the material tested. Observations are part of the testing process during the routine inspections. Due to the subjective nature of corrosion testing, pass/ fail determination is subject to customer inspection only.

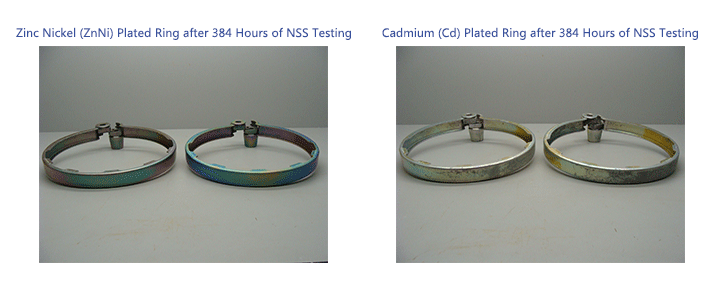

Zinc Nickel vs. Cadmium Plated Ring Test

Test: 384 Hours of Continuous NSS (Neutral Salt Spray) testing on both Zinc Nickel (ZnNi) and Cadmium (Cd) plated rings.

Result: Zinc Nickel outperformed the cadmium plated rings. No white corrosion is present on any of the zinc nickel plated samples.

Purchase from AFT or Supply Your Own Parts

When having parts zinc-nickel plated at our metal finishing facility, AFT offers customers the option to either supply their own parts or purchase them directly through AFT. In most circumstances, buying the parts directly from AFT can be significantly less expensive due to lower shipping costs and our competitive pricing.

We offer low minimums, and turn-around times are typically within 7 days. Please contact us with any questions or to request a quote.