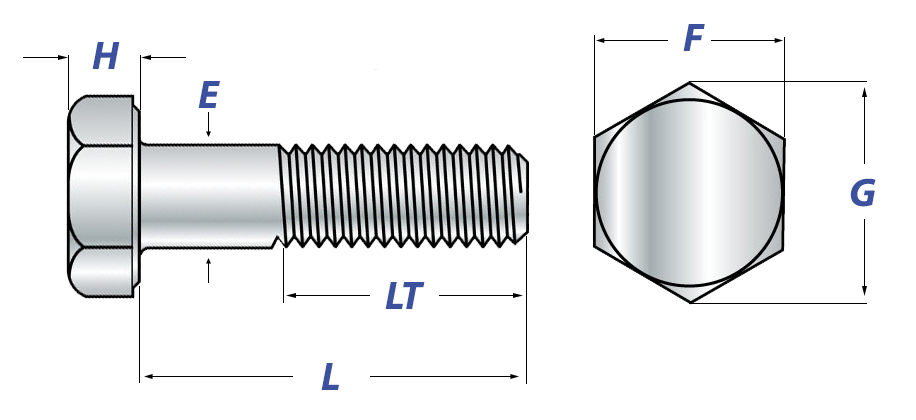

| Hex Cap Screws: Head & Thread Dimensions | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

Nominal or Basic Product Diameter |

Body Diameter (E) | Width Across Flats (F) |

Width Across Corners (G) | Head Height (H) | Thread Length (LT) | ||||||||

| Max | Min | Basic | Max | Min | Max | Min | Basic | Max | Min | <or=6" | >6" | ||

| 1/4 | .2500 | .2500 | .2450 | 7/16 | .438 | .428 | .505 | .488 | 5/32 | .163 | .150 | .750 | 1.000 |

| 5/16 | .3125 | .3125 | .3065 | 1/2 | .500 | .489 | .577 | .557 | 13/64 | .211 | .195 | .875 | 1.125 |

| 3/8 | .3750 | .3750 | .3690 | 9/16 | .562 | .551 | .650 | .628 | 15/64 | .243 | .226 | 1.000 | 1.250 |

| 7/16 | .4375 | .4375 | .4305 | 5/8 | .625 | .612 | .722 | .698 | 9/32 | .291 | .272 | 1.125 | 1.375 |

| 1/2 | .5000 | .5000 | .4930 | 3/4 | .750 | .736 | .866 | .840 | 5/16 | .323 | .302 | 1.250 | 1.500 |

| 9/16 | .5625 | .5625 | .5545 | 13/16 | .812 | .798 | .938 | .910 | 23/64 | .371 | .348 | 1.375 | 1.625 |

| 5/8 | .6250 | .6250 | .6170 | 15/16 | .938 | .922 | 1.083 | 1.051 | 25/64 | .403 | .378 | 1.500 | 1.750 |

| 3/4 | .7500 | .7500 | .7410 | 1-1/8 | 1.125 | 1.100 | 1.299 | 1.254 | 15/32 | .483 | .455 | 1.750 | 2.000 |

| 7/8 | .8750 | .8750 | .8660 | 1-5/16 | 1.312 | 1.285 | 1.516 | 1.465 | 35/64 | .563 | .531 | 2.000 | 2.250 |

| 1 | 1.0000 | 1.0000 | .9900 | 1-1/2 | 1.500 | 1.469 | 1.732 | 1.675 | 39/64 | .627 | .591 | 2.250 | 2.500 |

| 1-1/8 | 1.1250 | 1.1250 | 1.1140 | 1-11/16 | 1.688 | 1.631 | 1.949 | 1.859 | 11/16 | .718 | .658 | 2.500 | 2.750 |

| 1-1/4 | 1.2500 | 1.2500 | 1.2390 | 1-7/8 | 1.875 | 1.812 | 2.162 | 2.066 | 25/32 | .813 | .749 | 2.750 | 3.000 |

| 1-1/2 | 1.5000 | 1.5000 | 1.4880 | 2-1/4 | 2.250 | 2.175 | 2.598 | 2.480 | 1-5/16 | .974 | .902 | 3.250 | 3.500 |

* Click on the nominal size to find products.

| Hex Cap Screws : Tolerance on Length | |||||||

|---|---|---|---|---|---|---|---|

| Nominal Screw Size |

Nominal Screw Length | ||||||

| Up to 1" | Over 1" - 2-1/2" | Over 2-1/2" - 4" | Over 4" - 6" | Longer than 6" | |||

| 1/4 - 3/8 | -.03 | -.04 | -.06 | -.10 | -.18 | ||

| 7/16 & 1/2 | -.03 | -.06 | -.08 | -.10 | -.18 | ||

| 9/16 - 3/4 | -.03 | -.08 | -.10 | -.10 | -.18 | ||

| 7/8 and 1 | - | -.10 | -.14 | -.16 | -.20 | ||

| 1-1/8 - 1-1/2 | - | -.12 | -.16 | -.18 | -.22 | ||

| Hex Cap Screws : Performance & Mechanical Stats | ||||||

|---|---|---|---|---|---|---|

|

|

|

|

|

|

||

| Applications | Non-critical applications, economical | Greater tensile strength than Grade 2, Yield to tensile ratio is the lowest of all heat treated steels. | High stress applications | General corrosion resistance such as chemical or food-processing equipment | Greater corrosion resistance, strength and temperature | |

| Material |

Low or medium carbon steel. AISI - 1006-1050 | Medium carbon steel (or alloy), heat treated | Medium carbon alloy steel, heat treated | Austenitic alloys: 303, 303Se, 304, XM7 (chromium 17-19% and nickel content 8-10%) | 316 Stainless Steel (Molybdenum content 2-3% and nickel content 10-14%) | |

| Heat Treatment | N/A | Heat treated, oil or water quenched, tempered at 800 Deg (F) min. | Heat treated, oil quenched, tempered at 800 Deg (F) min. | |||

| Hardness |

1/4"-3/4" D, Up to 6" L: Rockwell B80-B100 1/4"-3/4" D, Over 6" L: Rockwell B70-B100 7/8"-1-1/2" D, all lengths: Rockwell B70-B100 |

See below | See below |

1/4"-5/8" D: Rockwell B95-C32 3/4"-1" D: Rockwell B80-C32 |

1/4"-5/8" D: Rockwell B95-C323 3/4"-1" D: Rockwell B80-C32 |

|

| Core Hardness | See above |

1/4"-1" D, all lengths: Rockwell C25-C34 1-1/8"-1-1/2" D, all lengths: Rockwell C19-C30 |

1/4"-1-1/2", all lengths: Rockwell C33-C39 | See above | See above | |

| Surface Hardness | See above |

1/4"-1" D, all lengths: Rockwell 30N54 max 1-1/8"-1-1/2" D, all lengths: Rockwell 30N50 max |

1/4"-1-1/2" D, all lengths: Rockwell 30N58.6 max | See above | See above | |

| Proof Load |

1/4"-3/4" D, Up to 6" L: 55,000 psi 1/4"-3/4" D, Over 6" L: 33,000 psi 7/8"-1-1/2" D, all lengths: 33,000 psi |

1/4"-1" D, all lengths: 85,000 psi 1-1/8"-1-1/2" D, all lengths: 74,000 psi |

1/4"-1-1/2" D, all lengths: 120,000 psi | |||

| Yield Strength |

1/4"-3/4" D, Up to 6" L: 57,000 psi min. 1/4"-3/4" D, Over 6" L: 36,000 psi min 7/8"-1-1/2" D, all lengths: 36,000 psi min |

1/4"-1" D, all lengths: 92,000 psi min

1-1/8"-1-1/2" D, all lengths: 81,000 psi min |

1/4"-1-1/2" D, all lengths: 130,000 psi min |

1/4"-5/8" D, 2.25 D and longer: 65,000 psi min 3/4" (2.25D and longer) & 7/8"-1" D (3D and longer): 45,000 psi min |

1/4"-5/8" D, 2.25 D and longer: 65,000 psi min 3/4" (2.25D and longer) & 7/8"-1" D (3D and longer): 45,000 psi min |

|

| Tensile Strength |

1/4"-3/4" D, Up to 6" L: 74,000 psi min. 1/4"-3/4" D, Over 6" L: 60,000 psi min 7/8"-1-1/2" D, all lengths: 60,000 psi min |

1/4"-1" D, all lengths: 120,000 psi min

1-1/8"-1-1/2" D, all lengths: 105,000 psi min |

1/4"-1-1/2" D, all lengths: 150,000 psi min |

1/4"-5/8" D, 2.25 D and longer: 100,000-150,000 psi 3/4" (2.25D and longer) & 7/8"-1" D (3D and longer): 85,000-140,000 psi |

1/4"-5/8" D, 2.25 D and longer: 100,000-150,000 psi 3/4" (2.25D and longer) & 7/8"-1" D (3D and longer): 85,000-140,000 psi |

|

| Elongation | 18% min | 14% min | 12% min | 4D - 1/4"-5/8" D: 20% min, 3/4"-1" D: 25% min | 4D - 1/4"-5/8" D: 20% min, 3/4"-1" D: 25% min | |

| Reduction of Area | 35% min | 35% min | 35% min | |||