What is Nickel Plating?

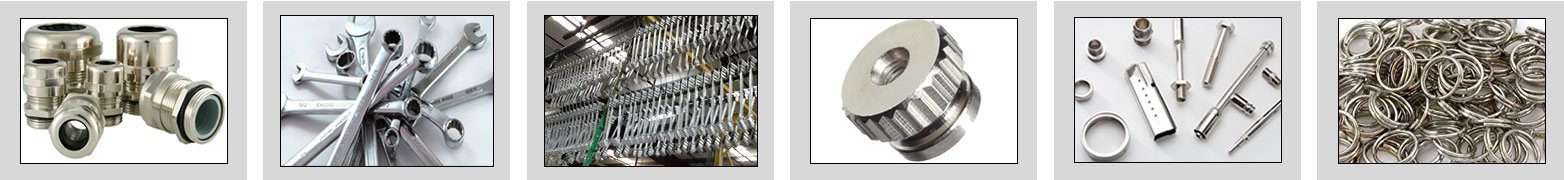

Nickel plating can be deposited in a variety of ways - soft or hard, dull or bright, depending on the application process used. Nickel plating is often applied over copper and under cadmium for a decorative finish.

Bright nickel plating is a highly reflective finish, therefore the need for polishing is often eliminated. Because nickel is such a hard metal with relatively poor ductility, when possible, parts should be bent into their final shape before the bright nickel plating is applied.

Once the piece has been prepared, it is immersed into an electrolyte solution and is used as the cathode. The nickel anode is dissolved into the electrolyte in form of nickel ions. The ions travel through the solution and deposit on the cathode.

What are the advantages of Nickel Plating?

- Decorative finish on bright nickel plated bolts, nuts and screws

- Wear resistant

- Tarnish resistant

- Good diffusion barrier

- Magnetic characteristics

- Suitable for either Rack or Barrel Plating

What are the common uses for Nickel Plated parts?

- Bright Nickel is great for fasteners and small components for a decorative finish

- Hand Tools

- Household lighting and plumbing fixtures

Nickel Plating Specifications

QQ - N -290 A

Purchase from AFT or Supply Your Own Parts

When having parts plated, coated, or painted at our metal finishing facility, AFT offers customers the option to either supply their own parts or purchase them directly through AFT. In most circumstances, buying the parts directly from AFT can be significantly less expensive due to lower shipping costs and our competitive pricing.

We offer low minimums, and turn-around times are typically within 7 days. Please contact us with any questions or to request a quote.