What is Passivation?

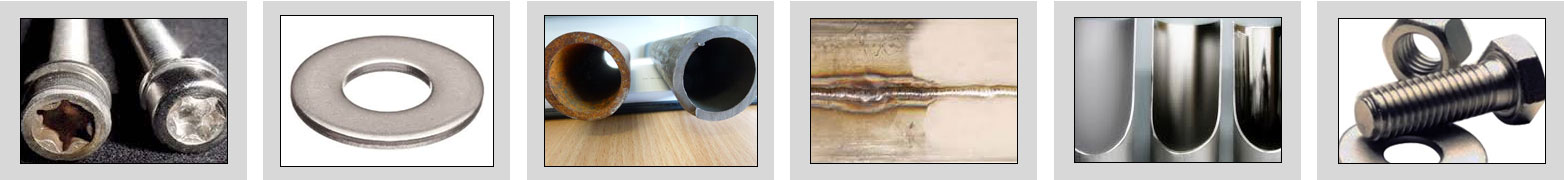

Passivation, or passivating, is the process to remove "free iron" contamination on stainless steel that is left behind from machining and fabrication. This is done by means of a chemical dissolution, most typically by an acid solution treatment that will remove the surface contamination, but will not significantly affect the stainless steel itself.

If the contaminations are not removed, this could lead to premature corrosion and deterioration of the component. Passivating stainless steel also facilitates the formation of a thin, transparent oxide film that protects the stainless steel from selective oxidation (corrosion).

What are the advantages of passivating stainless steel?

- Improves corrosion resistance

- Surface rust removal

- Removal of surface iron from machining process

- Enhances protective passive film

- Improves and extends the life of the product

AFT's Passivation Production Capacity

- High volume rack and barrel

- Nitric Acid Passivation

- Citric Acid Passivation

Passivation Specifications

- QQ-P-35C

- ASTM A380-99

- AMS STD-753

- AFT will meet or exceed most private specifications and standards.

Purchase from AFT or Supply Your Own Parts

When having parts plated, coated, or painted at our metal finishing facility, AFT offers customers the option to either supply their own parts or purchase them directly through AFT. In most circumstances, buying the parts directly from AFT can be significantly less expensive due to lower shipping costs and our competitive pricing.

We offer low minimums, and turn-around times are typically within 7 days. Please contact us with any questions or to request a quote.