| Combination Tooth Internal-External Lock Washers (ASME B18.21.1 2009) | |||||||

|---|---|---|---|---|---|---|---|

|

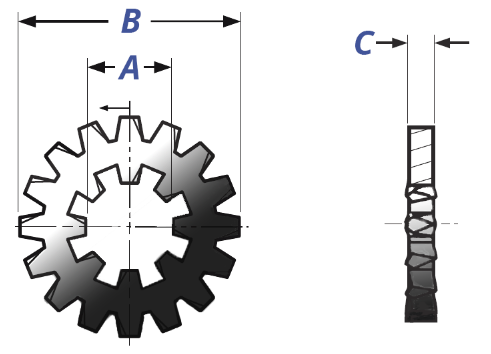

Nominal Washer Size |

A |

B |

C |

||||

|

Inside Diameter (ID) |

Outside Diameter * (OD) |

Thickness (TH) |

|||||

| Max | Min | Max | Min | Max | Min | ||

| 4 | 0.112 | 0.123 | 0.115 | 0.475 | 0.460 | 0.021 | 0.016 |

| 6 | 0.138 | 0.150 | 0.141 | 0.510 | 0.495 | 0.028 | 0.023 |

| 8** | 0.164 | 0.176 | 0.168 | 0.506 | 0.494 | 0.028 | 0.023 |

| 8 | 0.164 | 0.176 | 0.168 | 0.610 | 0.580 | 0.034 | 0.028 |

| 10 | 0.190 | 0.204 | 0.195 | 0.610 | 0.580 | 0.034 | 0.028 |

| 1/4 | 0.250 | 0.267 | 0.256 | 0.760 | 0.725 | 0.040 | 0.032 |

| 5/16 | 0.312 | 0.332 | 0.320 | 0.900 | 0.865 | 0.040 | 0.032 |

| 3/8 | 0.375 | 0.398 | 0.384 | 0.985 | 0.965 | 0.045 | 0.037 |

| 7/16 | 0.438 | 0.464 | 0.448 | 1.070 | 1.045 | 0.050 | 0.042 |

| 1/2 | 0.500 | 0.530 | 0.512 | 1.260 | 1.220 | 0.055 | 0.047 |

| 5/8 | 0.625 | 0.663 | 0.640 | 1.410 | 1.380 | 0.060 | 0.052 |

*Industry standards allow for washers with larger outside diameter dimensions.

**ITW Shakeproof specification, not ASME B18.21.1

|

|

|

Applications/ Advantages |

Lockwasher preferred in the following circumstances: (1) where a bigger bearing surface is desired; |

|

Material |

Steel: SAE 1050 - 1065 spring steel. |

| Hardness |

Steel: Rockwell C40 - 50. |

| Plating |

Steel: See more information above on the plating of steel lock washers. |