In today's fast-paced and highly competitive business landscape, efficient inventory management is no longer just an advantage—it's a necessity. Businesses are constantly seeking ways to optimize their operations, reduce costs, and enhance customer satisfaction, and at the heart of these efforts lies a robust inventory management system.

AFT's comprehensive offering of inventory management programs is meticulously designed to empower businesses of all sizes to gain unparalleled control over their stock, streamline their supply chain, and unlock significant operational efficiencies. From real-time tracking to predictive analytics, our solutions provide the tools and insights you need to transform your inventory from a complex challenge into a strategic asset.

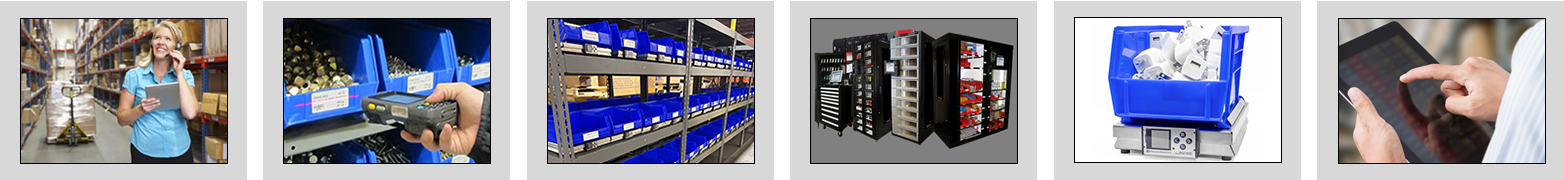

AFT's Vendor Managed Inventory (VMI) solutions include but are not limited to:

Weight-Based Inventory Systems:

Precision weight-based inventory scales provide real-time, automated tracking to help you maintain optimal inventory levels and reduce waste.

- Accurate, Real-Time Monitoring – Track stock levels instantly without manual checks

- Automated Alerts – Reports and notifications when inventory reaches critical levels

- Seamless Integration – Works with your existing systems

- Scalable Solutions – Perfect for warehouses, manufacturing, medical and industrial

- "Shelf" or "Hanging" Scale Styles - Solutions for shelves, walls or racks

- Safe and Secure - With 24/7 cloud-based monitoring capabilities, system performance and monitoring can be performed by any authorized party.

Customers have the option for AFT to monitor and restock your inventory or for AFT to monitor and we'll ship the product for your compnay to restock.

Standard Vendor-Managed Inventory (VMI):

Many of our customers rely on vendor-managed inventory. This approach gives AFT the responsibility for maintaining an agreed upon inventory level. We'll visit your location weekly, or monthly, depending on your volume of usage and will automatically restock your inventory.

Automated Vending Manager (AVM):

Ensure your critical inventory is always in stock and key tools are readily available with an Automated Vending Manager from AFT Fasteners. Available in drawer, locker, carousel, and cabinet styles, we can create the solution that's right for you.

Many of the styles feature:

- Easy Access Touchpad

- Accessed via WIFI

- Real Time Reporting

- 365 Day Software Support

- Low Stock Alerts

- And much more.

Why do companies choose automated vending management?

- Reduce Consumption - On average, companies will see a 30% reduction for tools/parts included in the managed inventory.

- Increase Productivity - Parts are readily available to the workers with little to no downtime searching for the correct parts or waiting for out-of-stock parts to be reordered.

- Automate Ordering - AFT will monitor and refill the machines automatically, or per your request.

- Departmental Tracking - Automated vending management allows for companies to track each department's usage to allow for proper billing and allocation.

What types of parts/products can we include?

AFT has worked with all types of industries, and we can find a solution to fit your specific needs. We've seen great success with the following types of products:

- Fasteners

- Drill Bits

- Hand Tools (Screwdrivers, Pliers, Wrenches, Utility Knives, Socket Sets)

- Abrasives (Grinding Wheels, Sandpaper, Files, Wire Wheels, Industrial Pads)

- Office Supplies (Pens, Batteries, Paper, Staples, Scissors, Tape)

- Safety Products (Gloves, Safety Glasses, Ear Plugs, Hard Hats, Safety Vests, Respirators/Masks)

- Electrical Products (Cable Ties, Terminals & Wire Connectors, Electrical Hand Tools, Fuses)

"Just In Time" (JIT) Inventory:

The "Just In Time" (JIT) inventory strategy is a powerful approach many companies leverage to dramatically boost efficiency and slash waste. With JIT, you receive goods only as they're needed for production or sale, eliminating the costs and risks associated with holding excess stock. This lean methodology minimizes storage expenses, reduces the likelihood of obsolescence, and frees up capital that would otherwise be tied up in inventory. However, the success of JIT hinges on your ability to accurately forecast demand, ensuring materials arrive precisely when required to avoid disruptions.

To further enhance the benefits of JIT, many of our customers utilize blanket orders. This involves placing a single order for your entire year's estimated needs, then releasing specific quantities as they're needed throughout the year. This proactive approach offers significant advantages:

- Price Lock-In: You secure your pricing for the entire year, protecting you from potential market fluctuations and allowing for more predictable budgeting.

- Guaranteed Stock: By committing to an annual volume, you ensure your essential products are always available when you need them, preventing costly stockouts and delays.

- Streamlined Procurement: Reduce administrative overhead by consolidating multiple smaller orders into one annual agreement.

By combining the precision of JIT with the foresight of blanket orders, businesses can achieve an even higher level of operational efficiency and cost control.

U-Scan It/Barcode Managed Inventory:

This type of customer inventory management is simple and straight-forward. We'll work with your company to create an organized system with barcoded bins. When your supplies are low, just scan the barcode and submit your requirements to AFT.

Please contact AFT Fasteners today to learn more about our inventory management services.