| Regular & High Alloy Split Helical Spring Lock Washers (ASME B18.21.1-1999) | ||||||

|---|---|---|---|---|---|---|

|

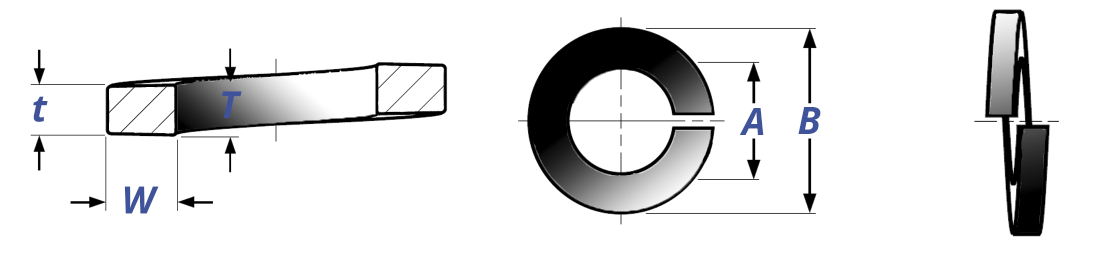

Nominal Washer Size |

A |

B |

(T+t) |

W |

||

|

Inside Diameter (ID) |

Outside Diameter (OD) |

Mean Section Thickness |

Section Width |

|||

| Max | Min | Max | Min | Min | ||

| #2 | 0.086 | 0.094 | 0.088 | 0.172 | 0.020 | 0.035 |

| #3 | 0.099 | 0.107 | 0.101 | 0.195 | 0.025 | 0.040 |

| #4 | 0.112 | 0.120 | 0.114 | 0.209 | 0.025 | 0.040 |

| #5 | 0.125 | 0.133 | 0.127 | 0.236 | 0.031 | 0.047 |

| #6 | 0.138 | 0.148 | 0.141 | 0.250 | 0.031 | 0.047 |

| #8 | 0.164 | 0.174 | 0.167 | 0.293 | 0.040 | 0.055 |

| #10 | 0.190 | 0.200 | 0.193 | 0.334 | 0.047 | 0.062 |

| #12 | 0.216 | 0.227 | 0.220 | 0.377 | 0.056 | 0.070 |

| 1/4 | 0.250 | 0.260 | 0.252 | 0.487 | 0.062 | 0.109 |

| 5/16 | 0.312 | 0.322 | 0.314 | 0.583 | 0.078 | 0.125 |

| 3/8 | 0.375 | 0.385 | 0.377 | 0.680 | 0.094 | 0.141 |

| 7/16 | 0.438 | 0.450 | 0.440 | 0.776 | 0.109 | 0.156 |

| 1/2 | 0.500 | 0.512 | 0.502 | 0.869 | 0.125 | 0.171 |

| 9/16 | 0.562 | 0.574 | 0.564 | 0.965 | 0.141 | 0.188 |

| 5/8 | 0.625 | 0.641 | 0.628 | 1.073 | 0.156 | 0.203 |

| 3/4 | 0.750 | 0.766 | 0.753 | 1.265 | 0.188 | 0.234 |

| 7/8 | 0.875 | 0.894 | 0.878 | 1.459 | 0.219 | 0.266 |

| 1 | 1.000 | 1.024 | 1.003 | 1.656 | 0.250 | 0.297 |

| 1-1/8 | 1.125 | 1.153 | 1.129 | 1.847 | 0.281 | 0.328 |

| 1-1/4 | 1.250 | 1.280 | 1.254 | 2.036 | 0.312 | 0.359 |

| 1-3/8 | 1.375 | 1.408 | 1.379 | 2.219 | 0.344 | 0.391 |

| 1-1/2 | 1.500 | 1.534 | 1.504 | 2.419 | 0.375 | 0.422 |

| 1-3/4 | 1.750 | 1.789 | 1.758 | 2.679 | 0.389 | 0.424 |

| 2 | 2.000 | 2.039 | 2.008 | 2.936 | 0.422 | 0.427 |

|

|

|

||||||||||||||

Applications/ Advantages |

|

||||||||||||||

|

|

|

||||||||||||||

Hardness |

|

||||||||||||||

Twist Test |

|

||||||||||||||

| Plating |

|

||||||||||||||