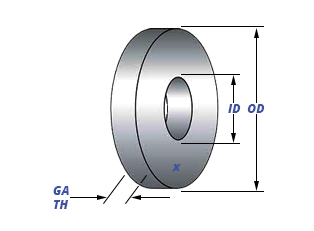

| Fender Washers | ||||||

|---|---|---|---|---|---|---|

|

Click on the size to shop products |

|

|

Thickness (TH) |

Approx. number of STEEL washers per carton | ||

| Max | Min | 50 Lbs. (Zinc, Black Oxide or Plain finish) |

20 Lbs. |

|||

| 10 | .219 | .688 | .080 | .036 | 9530* | - |

| 10 | .219 | .750 | .080 | .036 | 8000 | - |

| 10 | .219 | .875 | .080 | .036 | 5000 | - |

| 10 | .219 | 1.000 | .084 | .036 | 3500 | - |

| 10 | .219 | 1.250 | .084 | .036 | 2145 | - |

| 10 | .219 | 1.500 | .080 | .036 | 1760* | - |

| 10 | .219 | 2.000 | .080 | .036 | 796 | - |

| 1/4 | .281 | 1.000 | .132 | .036 | 3750 | 1500 |

| 1/4 | .281 | 1.250 | .132 | .036 | 2300 | 921 |

| 1/4 | .281 | 1.500 | .132 | .036 | 1550 | 620 |

| 1/4 | .281 | 1.750 | .080 | .036 | 1100 | - |

| 1/4 | .281 | 2.000 | .080 | .036 | 810 | 324 |

| 5/16 | .344 | 1.000 | .080 | .036 | 4670* | - |

| 5/16 | .344 | 1.250 | .132 | .036 | 2400 | 960 |

| 5/16 | .344 | 1.500 | .132 | .036 | 1600 | 640 |

| 5/16 | .344 | 2.000 | .080 | .036 | 820 | 328 |

| 5/16 | .344 | 2.500 | .080 | .036 | 500 | 200 |

| 3/8 | .406 | 1.250 | .132 | .036 | 2350 | 760 |

| 3/8 | .406 | 1.500 | .132 | .036 | 1650 | - |

| 3/8 | .406 or .422 | 1.750 | .132 | .051 | 1130 | 458 |

| 3/8 | .422 | 2.000 | .080 | .051 | 975 | 380 |

| 3/8 | .422 | 2.500 | .080 | .051 | 512 | 267 |

| 1/2 | .531 | 1.250 | .080 | .051 | 2675 | 1070 |

| 1/2 | .531 | 1.500 | .080 | .051 | 2000 | 720 |

| 1/2 | .531 | 1.750 | .080 | .051 | 1075 | 425 |

| 1/2 | .531 | 2.000 | .132 | .051 | 850 | 338 |

| 1/2 | .531 | 2.500 | .080 | .051 | 668 | 250 |

| 1/2 | .531 | 3.000 | .080 | .051 | 355 | 150 |

| 5/8 | .688 | 1.250 | .084 | .074 | 3590* | - |

| 5/8 | .688 | 2.000 | .080 | .051 | 1015 | - |

| 5/8 | .688 | 3.000 | .080 | .051 | 365 | - |

| 3/4 | .812 | 2.000 | .080 | .051 | 1155* | - |

| 7/8 | .938 | 2.500 | .118 | .101 | 715* | - |

*Represents a count based on stainless steel washers.

Description |

A flat washer with a greater surface area than a washer for USS or SAE. They are also produced from a |

||||||||||||||

Applications/ Advantages |

Used where an additional large surface of the bearing is needed. They were originally intended for |

||||||||||||||

|

|

Steel |

Stainless Steel |

|||||||||||||

|

Washers are to be punched from hot-rolled, hot-rolled and pickled, cold rolled steel or machined from bar stock or tubing or may be forged at the |

316 or 18-8 Stainless Steel. |

||||||||||||||

Plating |

Usually fender washer are zinc plated or come without a finish. |

|

|||||||||||||